Setup and Optimize the National Instruments PXI-5441 Waveform Generator

The National Instruments PXI-5441 is a powerful PXI waveform generator designed to support high-speed waveform downloads up...

As the test equipment industry evolves, businesses are replacing their outdated equipment parts with the newest available models on the market. While the benefits of upgrading to the latest updates are undeniable, a large amount of e-waste is created from newly decommissioned systems. With a problem of this scale, many are turning to eco-friendly recycling initiatives for the solution. At Apex Waves, we are addressing this issue directly with our Sell Your Surplus program. It is clear that properly recycling decommissioned systems and re-using obsolete parts through this program has a strong positive impact across multiple industries.

What Exactly is E-Waste?

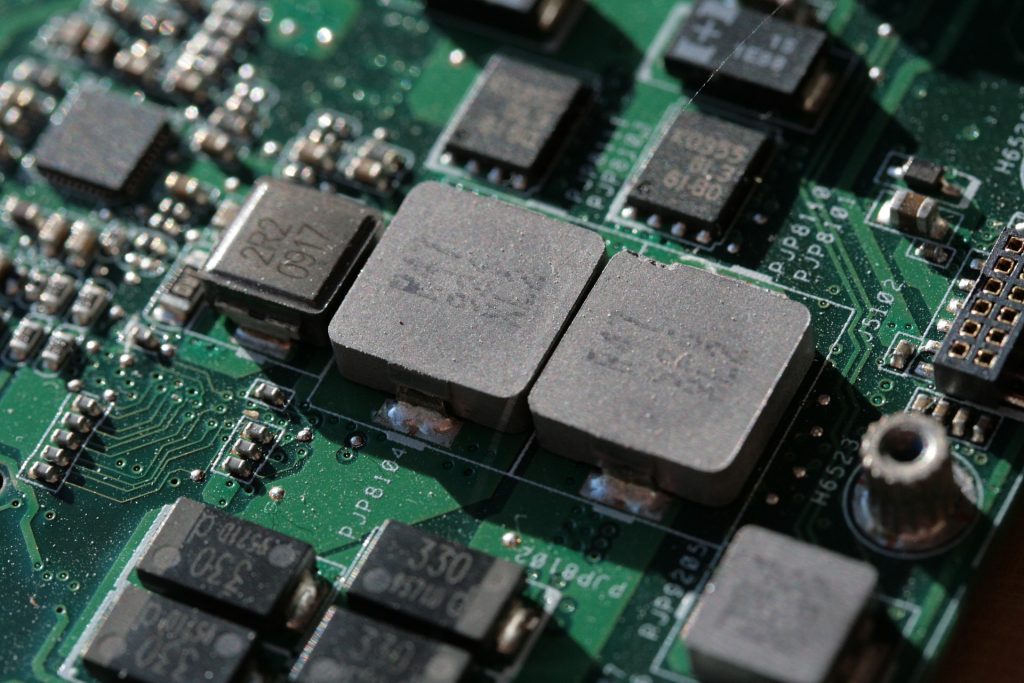

Electronic waste (e-waste) refers to electronic devices and parts that have been decommissioned because they are no longer of use. Despite the name, e-waste is full of valuable components that can be recycled and reused. Elements such as gold, silver, cobalt, copper, palladium, platinum, lithium, are all used to make electronic equipment. These materials find new life with the electronic recycling process.

What is The Process to Recycle E-Waste?

1) Collecting. E-waste is collected through a variety of means; specified bins, unique collection locations, or take-back programs such as Apex Waves’ Sell Your Surplus program. (Through this program, we purchase and test National Instruments parts that are labeled as obsolete, discontinued, or End of Life).

2) Storing. Due to the specific hazards and contaminants present in many electronic parts, secure and proper storage is incredibly important.

3) Dismantling. Before the e-waste can be processed, specific components have to be separated and sorted. This breaking down into individual parts allows for an even more accurate sorting of all of the materials.

4) Magnetic / Water Separation. Breaking down e-waste components where the pieces are placed mere centimeters apart requires the use of mechanical separation. The two methods used for this process are magnetic separation and water separation. With magnetic separation, the e-waste is first shredded, and then sent through a large magnet that separates the ferrous and nonferrous metals. With water separation, a steady stream separated components such as plastic and glass.

5) Recovering. At this final step, the sorted materials from the e-waste are now ready to be sold or reused.

The Environmental Impact of Recycling

The foremost concern when it comes to e-waste is the amount of harm it can cause the environment. Most electronic parts contain some amount of hazardous elements including PVC, mercury, fire retardants, or lead. Without recycling, e-waste from test equipment lays in a landfill and discharges harmful compounds into the air when heated by the sun. Poisonous contaminants leak into groundwater, affecting countless species on both the land and sea. According to estimates, between 20 and 50 million tons of e-waste are created annually across the globe. By safely recycling these parts and properly disposing of these contaminants, they are kept out of major landfills and harmful chemicals are prevented from entering into the environment.

Recycling in-demand test equipment also benefits the environment by meeting the need for specific parts. This reduces the need for manufacturing, which in turn conserves energy, conserves raw resources, and reduces pollution.

How Apex Waves is Making a Difference

The COVID-19 pandemic has had an unprecedented impact on the global supply chain, directly affecting the manufacturing and selling of electronic equipment. These recent events have only emphasized how recycling e-waste is not only beneficial for the environment, but for the economy as well.

Through our Sell Your Surplus program, Apex Waves is filling in the gaps by keeping decommissioned parts out of landfills and helping business owners with obsolete tech. It is not always feasible for a business to upgrade to the newest model parts. As a result, it may be a challenge to find a specific part for a now decommissioned system. With this program, these particular parts become much more accessible for the industries and companies that need them.

How does it work? When it comes time to upgrade your National Instruments parts, whether they are labeled as obsolete, discontinued, or End of Life- choose Apex Waves! We will pay you to give your parts new life. We make it easy by paying the shipping costs and sending you packing supplies and labels. We even offer personal pickup, where we will come to your site and haul your NI hardware ourselves.

Apex Waves is working to help manage obsolescence and protect our environment. Our efforts are helping to keep e-waste and decommissioned materials out of landfills, minimize supply chain complications, shorten delivery timeframes, and cover availability gaps for a variety of items.

Resources:

https://news.climate.columbia.edu/2018/08/27/growing-e-waste-problem/

https://www.rts.com/blog/the-complete-e-waste-recycling-process/

https://newtechrecycling.com/lab-test-equipment-recycling/

https://sadoffelectronicsrecycling.com/blog/e-recycling-role-in-easing-supply-chain-constraints/

A monthly email packed with valuable content—industry news, tutorials, obsolescence updates, and more. No sales pitches, just insights we think you'll find helpful!

The National Instruments PXI-5441 is a powerful PXI waveform generator designed to support high-speed waveform downloads up...

Companies in almost every industry are being transformed by artificial intelligence, and autonomous machines are...

The PXIe Platform from National Instruments offers an incredibly valuable toolset for test and measurement innovation. Its...

It is no secret that simulation and testing is an important part of designing circuits....