The analog meter, a classic measurement instrument, has long been the cornerstone of many sectors, including electrical engineering and mechanical diagnostics. Measuring physical values such as voltage, current, temperature, pressure, and more is the main use of an analog meter. Unlike their digital counterparts, analog meters use a moving needle or dial along a scale to provide a rapid and simple visual representation of data.

Analog Meter Basics

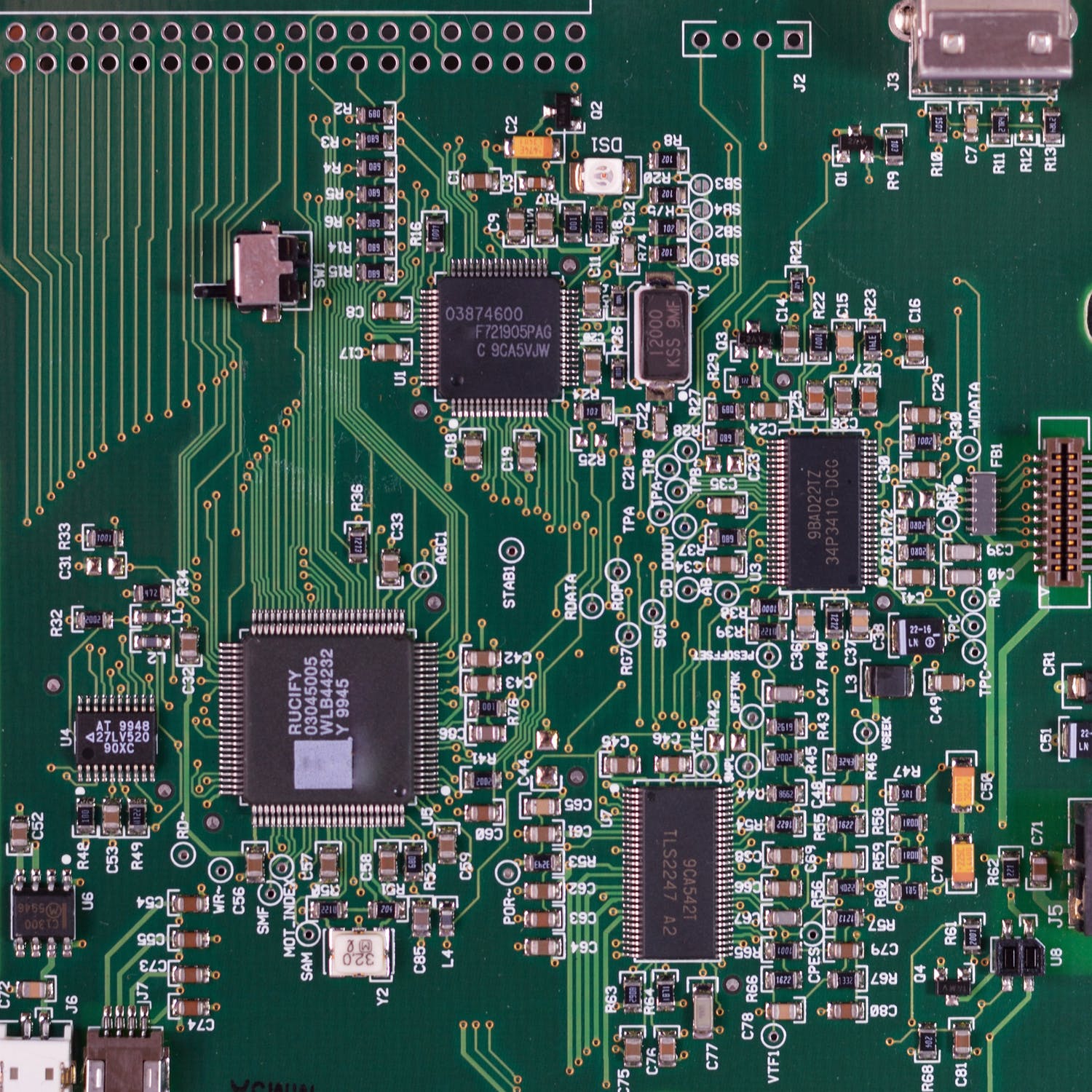

Analog meters consist of multiple components that measure and display physical values. The sensing component, intended to directly interact with the measured quantity, is at the center of this construction. This could take the form of an analog voltmeter, for example, where a coil of wire interacts with a magnetic field and moves in response to the voltage applied across it. Similar to this, the sensing element of an analog ammeter might be a shunt resistor, which would allow current to be measured as it flows through. Through the use of a movement mechanism—typically a coil of wire experiencing a force proportionate to the current flowing through it—this interaction is then converted into a visible indicator.

Why Is It Important to Know?

Understanding analog meters and how they work is essential across various professions, including electrical engineering, electricians, instrumentation technicians, HVAC technicians, automotive mechanics, and scientific researchers. These meters serve as foundational tools for measuring voltage, current, resistance, and other electrical parameters.

In electrical engineering, for example, professionals often rely on analog meters for circuit design, troubleshooting, and safety assessment tasks. Electricians use these tools to diagnose faults in electrical systems, while instrumentation technicians may employ them for process monitoring and control in industrial settings. Overall, the analog meter is an efficient way to test system performance and diagnose electrical issues, which is why it’s beneficial to understand its capabilities.

If your business requires an analog meter or other essential test equipment, Apex Waves can help! Browse our site to explore legacy test equipment, sell your surplus, or contact us for questions or concerns.

Challenges and Inaccuracies

Analog pointer meters have some built-in characteristic difficulties that require the user to closely analyze the pointer reading. This is partially because the numerals on the scale are written small due to space issues. It’s important to note that most meters do have some built-in inaccuracies, but the reading inaccuracies of the pointer and scale compound these. In some cases, inaccuracies can be tolerated, but in other cases, they cannot.

Digital Meters

Digital meters provide direct readouts with the actual numerals, which are recorded larger and easier to read. They are numerically specific and do not require scrutiny or interpretation to determine the reading. Another important consideration is that the built-in level of accuracy of the digital meter is not degraded by any reading or interpretation inaccuracies.

Test and Measurement Specifics

The three major test and measurement characteristics are current, voltage, and resistance. These are each interconnected by Ohm’s law, as taught in basic electricity.

Ohm’s law plays a crucial role in simplifying meter design by enabling circuits to be configured in such a way that one characteristic can be used to determine others to be measured. For instance, utilizing Ohm’s law, current can serve as an indicator for voltage or resistance, and vice versa. This principle becomes evident when considering that resistance (R) equals voltage (V) divided by current (I), denoted as R = V/I. Therefore, if a meter utilizes a standard, known voltage source, the resulting current flow indicates the amount of resistance that allowed that current. Conversely, following the equation V = IR, if the meter incorporates a standard, known resistance in its circuit, the observed current flow indicates the voltage that caused it.

Analog or pointer meter movements capitalize on the effects of current flow not only to measure current but also to gauge voltage and resistance, all in accordance with Ohm’s law. Conversely, meters employing built-in amplifiers typically respond primarily to voltage as the primary measurement characteristic, again employing Ohm’s law to calculate current and resistance. This principle holds true for both analog and digital meters equipped with built-in amplifiers, illustrating the versatility and applicability of Ohm’s law across various meter designs and technologies.

Analog Meters in Modern Applications

Despite their age-old architecture, analog meters are inevitably useful in a variety of contemporary applications across several industries. Analog meters are widely used in electrical engineering because of their dependability and real-time reaction for measuring voltage, current, and resistance. They continue to be essential instruments for electrical circuit troubleshooting, offering immediate feedback that helps identify issues and guarantee peak performance. Furthermore, analog meters provide a practical and easy-to-use means of monitoring vital data in domains like HVAC systems and vehicle diagnostics, empowering personnel to make well-informed decisions quickly and efficiently.

In addition, analog meters are admired for their ability to withstand challenging conditions and electromagnetic interference that may cause their digital equivalents to malfunction. Analog meters are still essential for process monitoring and guaranteeing operational effectiveness in industrial settings like manufacturing facilities and refineries. They work effectively in these challenging conditions where accuracy and dependability are crucial because of their simplicity and endurance. Furthermore, analog meters are frequently used as failsafe instruments in vital systems, offering a backup in the event that digital instrumentation malfunctions or experiences technological issues.

Frequently Asked Questions

What is one of the most common uses of an analog meter?

It’s most common to use analog meters to measure electrical properties in electronic circuits, such as voltage, current, and resistance. For example, technicians, researchers, and engineers frequently utilize analog multimeters to test components, diagnose electrical systems, and confirm circuit functionality.

What is the most common analog signal?

The voltage signal is the most often used analog signal. Variations in electrical potential between two points in a circuit are represented by voltage signals, which are widely utilized in instrumentation, electronics, and telecommunications. In analog electronic systems, voltage signals can transmit data such as sensor readings, audio signals, and control signals. They are an essential part of analog signal processing and analysis because they are adaptable and simple to measure using analog meters or other instruments.

How accurate is an analog meter?

The design, construction, and calibration of the analog meter are just some of the factors that could potentially impact its accuracy. Even though analog meters are generally accurate, they might not be as exact as digital meters in some circumstances.

A percentage of full-scale deflection (% FSD) is commonly used to represent the accuracy of analog meters. For instance, a meter may be accurate to within ±2% FSD, meaning that the displayed reading may deviate from the real value by up to 2% throughout the meter’s complete range.