Particle accelerators touch our lives in a variety of ways, but the population at large is likely ignorant of their purpose or operation. Since their inception in the 1890s, these complex tools have been integral to important discoveries in basic science, scientific and medical research, the defense industry, and even many consumer products. National Instruments provides a beam position monitoring and electronics control solution that aids in the commercial use of particle accelerators.

What is a Particle Accelerator?

This highly complex piece of technology is an enclosed machine that speeds up elementary particles (electrons and protons) to incredible speeds and energy levels. These accelerated beams of charged particles can be used for numerous research endeavors. Basically, after the beam is moving rapidly, targets are placed in the path of the beam, along with measurement devices, to observe and record data about how the beam and the target react.

- A linear particle accelerator speeds the particles along a straight (linear) line. This type of accelerator is used for experiments with fixed targets.

- A circular particle accelerator speeds the particles around a circular track. This type of accelerator is used for experiments with colliding beams or fixed targets.

Both types of particle accelerators use electric fields to increase the energy and speed of the particle beams, and they use magnetic fields to control their aim and focus. The particle beams travel inside a vacuum sealed container, or pipe, to eliminate the possibility of contaminants or obstructions.

How Are Particle Accelerators Used in Research?

Since their invention, particle accelerators have been essential tools of discovery for basic questions about our universe at the molecular level. By observing how electrons and protons from different types of matter respond through testing in particle accelerators, physicists have gained a better understanding of the fundamental laws of matter, time, energy, and space.

Over 30,000 particle accelerators are in operation around the globe, opening doors to greater knowledge in a host of different industries and applications. In recent decades, scientific use of focused light beams has introduced many benefits to the worlds of physics, chemistry, biology, and healthcare. Modern x-rays and CT scans are but two common uses of this technology that can trace their existence and recent improvements back to basic research with particle accelerators.

Particle accelerators using electron beams have revealed much about the properties of various materials, which has led to new technology allowing for the alteration of many substances. Industries can now, for example, benefit from new technologies to strengthen plastic, which allows for its use in medical sterilization, food preparation, semiconductor manufacturing, and the creation of improved medical replacement joints for the human body.

Why and How is NI Involved with Particle Accelerators?

Particle accelerators in use today operate under demanding conditions and have extremely high standards for stability and control. This means the electronic measurement components used to position, aim, focus, and control high-intensity particle beams must meet or exceed stringent parameters for accuracy, precision, and range.

In a particle accelerator, the beam of focused particles must be detected, monitored, and measured in various ways at several different parts of the beamline. This leads to greater accuracy in experiments and the resulting data that is produced.

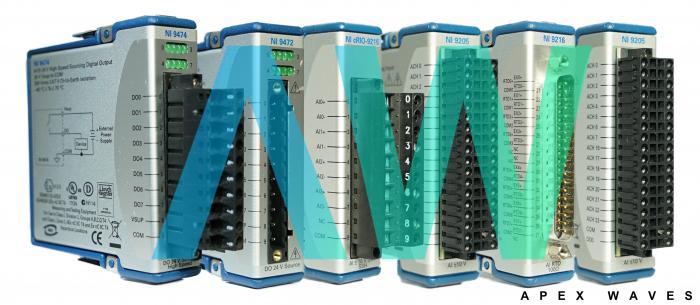

National Instruments’ Beam Position monitor (BPM) control electronics solution allows for highly accurate measurement of a particle beam’s various parameters, as well as providing the ability to correct the beam’s trajectory, “tune” the beam to different frequencies, and aim the beam for better centering and target connection. Companies can obtain NI modules from Apex Waves for plug-and-play use in building reliable test setups. This includes utilizing existing NI instruments like FlexRIO, PXI, and LabVIEW software to create customized measurement solutions.

Alexander Aleksandrov, from the Oar Ridge National Laboratory in eastern Tennessee, says, “The wide range of off-the-shelf ADCs and complementary modules available from NI combined with the flexibility of FlexRIO allowed us to develop a modern, large-scale accelerator BPM system with significantly fewer resources than any custom solution would require.”

For more information about NI’s solution for beam position monitoring and control electronics, call to speak directly with an NI representative or visit their website.